Next step in the frame building process is to figure out the rear triangle (I know, don’t have the main triangle quite done yet). This will be a track bike as you can see and will use a vintage style seat stay attachment flute.

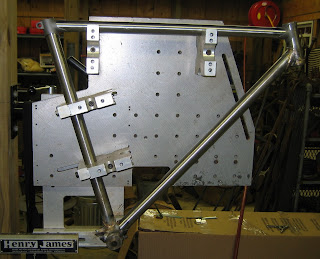

Makeshift Bicycle Alignment Table

I had a piece of 1 inch plate hanging around and jury rigged a bottom bracket holder. It worked pretty well. Need to work on the bottom bracket holder some more to get rid of the washers as they are not strong enough. But like I said it seemed to work well enough for now.

Bicycle Frame – Front Triangle Ready to Braze!

Slow Frame Building Progress

Not a lot going on in the frame building front. Working on getting an alignment table figured out before I can go much further. Will probably not get the frame complete by the time I go to the Handmade Bicycle Show in Feb.

First Lugged Joint – Bottom of Head Tube / Down Tube

My first brazed lug! I bit more brass than I probably needed so the cleanup was a bit much. I do think that the penetration of the joint was good though. I did some cold setting on it and it did not flinch. Overall I am pleased with the newbie attempt.

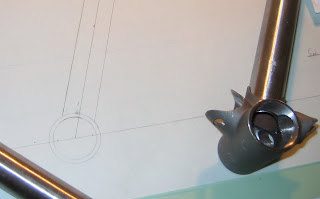

Getting Down Tube Length – Frame Layout

With the bottom bracket / seat tube down I can pull the down tube length from the drawing. Carefully aligning the frame over the drawing with the help of a machinist square and v-blocks I can now scribe the lines where the down tube intersects the bottom bracket. Also note, only the lug is only attached to the head tube at this point.

Frame Building -ST/ BB Weld Done!

The seat tube is brazed in the bottom bracket shell. I can start pulling off the rest of the dimensions from the drawing. I am using a reasonably flat surface from and old cast iron table saw.

Frame Drawing – Using the Paterek Method

Drawing out the first frame. Pretty much completed the drawing so I can get my final tube lengths and cut the final miters.

Drafting Table up and Running

Went old school and picked up a drafting table to hand draw my bicycle frames on!

Details and pics coming soon…