I have had this around the shop for some time. I just started playing with it again and added the pipe to it. I really like the way it is going…. It might be done but I will stare at it for a while.

Phil’s Frame – Front Triangle Prep Complete

Front triangle preparation is finished! Seat tube/bottom bracket is complete as well as the down tube and head tube. Next step, flux up those tubes and finish the rest of the main triangle welds.

Regatta – Experiment with interesting plow parts

Three Olive Progress

Alan Frame Cleaning up Nice!

Farmer 2

Phil’s Frame Underway!

Bird Bath – Found Object

Antique Bicycle Cable Machine

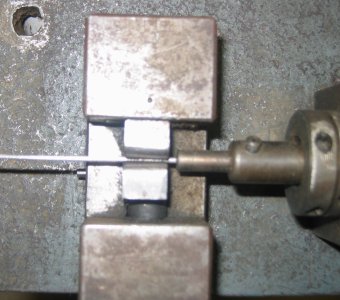

Here is a great device that I am still looking for info on. What I do know is that it is used in the creation of brake and shift cables. It has an attached cable cutter (Top left of photo). Bulk spools of cable (without ends) would be used to create any cable length you need.

Once the cable is cut the end would be “crunched” into the dies shown here. This process would create a very nice mushroom type end to the cable.

Cable End after “crunch”

This is where it gets tricky. As of yet I don’t have any info on how the ends (primarily made of lead) would be attached to the cables at this point. One thought would be that the cable with the mushroom end would be placed in a mold similar to a fishing sinker mold and the lead would be poured around it.

Other thought is that stock lead cable end were available to crimp onto the mushroom tip.

Still digging around for more info….