Looks like snow inside and out today. Did a fair amount of squaring on the mill today. Used fly cutter and an end mill. Still getting used to fly cutter … getting bit ground right has been most of the challenge. Mill size a bit if a challenge as well.

Vee Blocks for Seat and Chain Stays

1 Inch Headset Spacer

Used Glove Salesman – Davistown Museum

Liberty Tool Visit

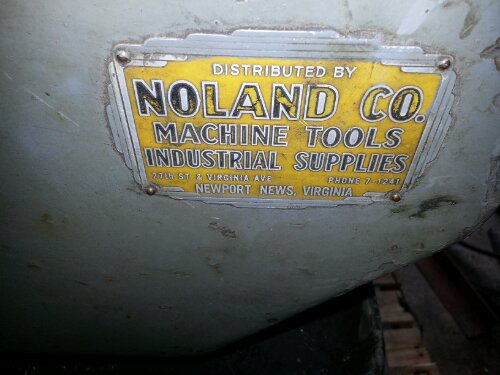

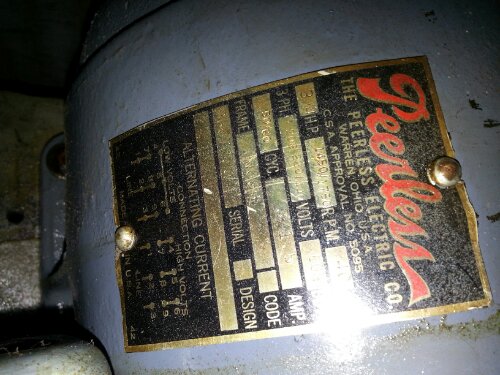

Sheldon is home

Some more pics just inside the shop. Got unloaded with help of come along and pry bar. Motor is 3/4 hp 3phase and gearbox assembly is in great shape.

Starting the shop rearranging tomorrow!

Sheldon XL 56 P

Picked up a lathe this weekend. Well, almost. Deposit down, pickup this weekend. It is a Sheldon XL 56 P.

Good working order, gears all good, ways in great shape and was able to view it cutting. More pics when I get her home.

Vise – Pedestal Complete

Got pedestal completed after much stress over height considerations. Ended up going a few inches below my elbow.

Next step: commit to a spot on the shop floor and bolt her down.

Vise – Setting up Permanent Pedestal

Finally setting up my vise for good! Building pedestal and will mount to floor. Sick of rattle and shake on Chinese vise attached to workbench. Picked this vise up last summer at Liberty Tool in Liberty Maine.

Will weld up soon and red head to the floor.

Side note: bored out the 3/4 and 9/16 holes on the millrite….made easy work of the 5/8″ plate.

Machine Shop taking Shape

Started cleaning up the shop and organizing it around the two recent milling machines that I found over the summer. Next steps, get vise situated on stand and fine a lathe sometime soon. Will start next frame soon enough as well.